Residual heat in East Flanders: from hidden source to industrial power

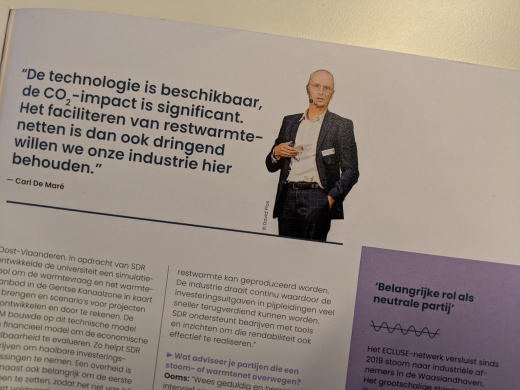

The latest issue of Playground Innovation Magazine, published by POM East Flanders and the Province of East Flanders, features a double interview with Carl De Maré (Programme Director at Smart Delta Resources Flanders) and Wim Ooms (Plant Manager at Indaver). East Flanders under steam is the central theme: how large-scale steam and heat networks, fuelled by residual heat, help companies to reduce CO₂ emissions, save costs and anchor industry in a sustainable way.

ECLUSE in Waaslandhaven has been supplying steam from waste incineration plants to industry since 2019. Capacity will soon double, resulting in an additional 100,000 tonnes of CO₂ savings per year.

North Sea Port: opportunities for heat exchange between SDR partners

North Sea Port also already has industrial heat and steam networks, but on a smaller scale. For example, Stora Enso supplies residual heat to Volvo Car Gent via a pipeline, enabling the car manufacturer to use green energy in its production. In addition, BEE (Belgian Eco Energy) supplies heat, steam and electricity to surrounding businesses via its power plant. Just across the border in Sluiskil, Yara supplies residual heat and CO₂ to the local horticultural sector, which not only improves energy efficiency but also encourages circular applications.

According to Carl De Maré (SDR Flanders), this is just the beginning: East Flanders has a lot of usable residual heat. With high-temperature heat pumps, we can upgrade it to steam for chemicals, steel and food.

Collaboration between SDR Flanders, POM East Flanders and Ghent University

Smart Delta Resources Flanders supports companies, together with Ghent University and POM East Flanders, in making optimal use of residual heat in the Flemish North Sea Port region. The project focuses on upgrading industrial residual heat to steam using high-temperature heat pumps. SDR supports companies with strategic insights and financial analyses, Ghent University has developed a simulation model for heat demand and supply, and POM has developed a financial model to assess economic feasibility.

Together, we want to accelerate investment decisions and create large-scale heat networks that drastically reduce CO₂ emissions and anchor industry in a sustainable way.

The Magazine is available in Dutch.